Plastic fabrication can be accomplished in a variety of ways. Common forming methods include extrusion, vacuum forming, injection molding and blow molding. From here, the new product can go through countless additional processes such as punching, stamping, bending, etching or engraving, cutting, drilling, tapping and assembly. Depending on the part, different attention must be paid and methods used. Plastic fabricators not only play a role in the manufacturing process, but they are able to assist in many designing methods as well. Fabricators are able to custom engineer many parts for particular uses in various industries. This is important for industries such as medical and food where the plastics will need to be free of toxins and contaminant resistant. Fabricators are also able to produce parts that are watertight and can resist exposure to a variety of substances. Some of the most advanced plastic products can handle abrasion, possess high levels of tensile strength and can resist chemicals, oils and moisture.

The benefits and uses of plastic products are endless. Many plastics are also easy to recycle, allowing them to be re-used and disposed of in ways that can help the environment. Recently, many have come to be concerned that plastics can be dangerous, especially ones that use materials such as BPA. Luckily, the manufacturing industry has begun to address such concerns and many fabricators make sure to use products and methods that expose the least amount of toxins or none at all. The FDA monitors such findings and investigates the claims. In the case of BPA, many manufacturers make sure that none of their products contain it. Many Nalgene bottles come with BPA Free labels, to show customers the changes they are willing to make to ensure safety. Many phthalates have also been banned in the US to ensure the safety of consumers. Such precautions are helping to further the plastic industry by promoting safe methods and materials in the creation of our uncountable plastic products. Plastic safety is important because it is often used to make children’s toys.

Plastic has so many uses in today’s world. The material is temperature resistant, long lasting and can be resistant to many different levels of environmental exposure including moisture, abrasive chemicals, vibration, pressure and even certain levels of impact. Then there are the possible forms, which seem limitless. Just think about kids’ toys these days. Not only are most of the toys themselves made out of different types of custom plastics in various shapes and sizes, such as Barbie’s shoes, but the packages they come in are equally diverse. The clamshell packaging surrounding a Barbie doll will not only form perfectly to her body, but it will be able to form around her extra dress, pair of shoes, hand bag and dog! In order to achieve these levels of perfection most processes today use CNC (computer numerically controlled) software. In using a computer, human error is virtually eliminated and the production of identical, complex parts has reached levels of speed and efficiency that before many would not imagine. Plastic plays one of the most important roles in today’s world and the benefits of plastic fabrication continue to increase every day.

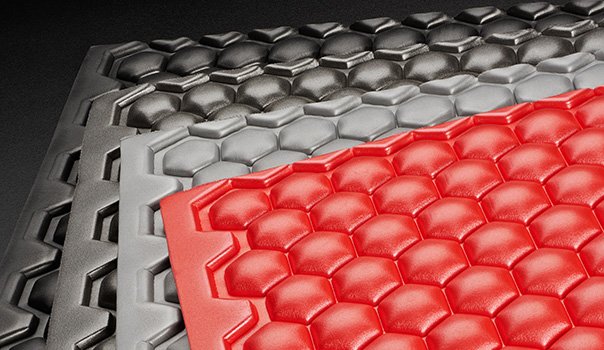

Die Cutting

Die Cutting Foam Fab

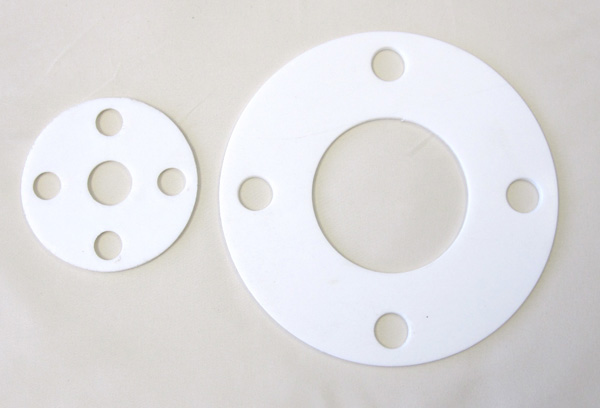

Foam Fab Gaskets

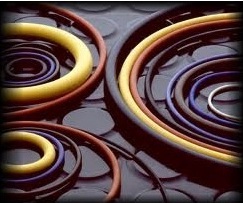

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services