There are plastic welding techniques that use an extra plastic strip to help connect the two separate pieces, while other methods melt an edge of each plastic part and push them together. After the plastic has cured (dried), a permanent, watertight seal remains. Only thermoplastics, those that are able to melt with the application of heat, are used for welding. Read More…

We are accomplished plastic fabricators. The usability of our products is unmatched. We offer a plethora of secondary services for optional features. All of engineers are extremely thorough when creating these plastics. Your satisfaction is essential to us. You can count on us to give you exactly what you are looking for. Give us a call today to learn more information!

At Park Plastic Products our main focus is manufacturing custom fabricated tanks from polypropylene and co-polymer. Chemical rinse tanks, dip tanks, anodizing tanks, tank liners, air purification tanks, drip pans and custom rolled polypropylene tanks are available to be built to your size and specifications.

Experts in unique custom plastic extrusion products and complex secondary fabrications, Northland Plastics specializes in custom plastic profile extrusions such as extruded plastic tubing, rigid plastic profiles and flexible plastic profiles. Call Northland Plastics, Inc. for all your extrusion needs.

Thrust Industries is committed to quality in everything it does, from its technical knowledge to its customer service. As a leading plastic fabricator, the entire team at Thrust is devoted to developing high-quality solutions for your business and delivering them exactly when you need them. Thrust has served the needs of customers across the globe for over 3 decades— become one of them today.

Comco Plastics, Inc. offers precision machined plastic and custom fabrication including vacuum forming and plastic parts. We have highly skilled machinists and an array of CNC equipment available. Pellet to part manufacturing capabilities. From R&D to applications, we have the experience you need.

More Plastic Welding Companies

These include polyvinyl chloride, high and low density polyethylene, polystyrene, polypropylene, polycarbonate and acrylic. Plastic welders usually use hot pressurized gas to melt the plastic together, but they also use ultrasonic vibration, lasers and friction. Many different parts are constructed by plastic welding, including tanks, containers like jugs and fuse-welded pipes. It is a similar process to metal welding, but it does not form as strong of a bond and is easier to accomplish. While the same type of plastics are usually welded together, different kinds can also bond together to form a single product.

There are five main methods of welding plastic parts together. Each technique uses a different approach but has similar results. The most popular and widely used is hot gas welding, where a welding gun releases hot, pressurized air and directs it on the pushed-together edges of the plastic parts.

Their molecular chains cross-link to form a single piece of plastic. While hot gas welding is highly effective, it takes large amounts of energy and is therefore inefficient. A plastic filler rod often aids this process. Ultrasonic welding, like its name suggests, generates heat with high frequency, low amplitude vibration, anywhere from 15 to 40 kHz.

It provides the fastest heat sealing and can go on for long periods of time. Friction/vibration welding takes the two separate pieces of plastic and rubs them together at a higher amplitude and lower frequency than ultrasonic welding. They are clamped together until cured. Hot plate welding is used to join two larger parts together, or those that have complex weld design.

Each plastic piece is attached to a platen of a press. A hot plate in the shape of the weld joint is moved over the two parts, melting the interfaces. The platens then press the pieces together and allow the joint to cool. Finally, laser welding uses an intense beam of light that moves along the joining line. This type of welding is for intricate joints, thin plastic pieces and for products that require the least visible seam possible.

Die Cutting

Die Cutting Foam Fab

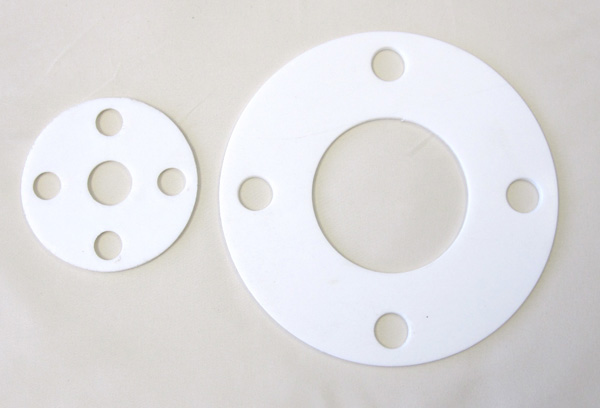

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services