A plastic product is a thing made of plastic that has a use. Since the development of the first plastic materials, the plastic research and development industry has exploded. Today, so many different plastic varieties exist that it can sometimes be difficult to distinguish them from each other. Read More…

We are accomplished plastic fabricators. The usability of our products is unmatched. We offer a plethora of secondary services for optional features. All of engineers are extremely thorough when creating these plastics. Your satisfaction is essential to us. You can count on us to give you exactly what you are looking for. Give us a call today to learn more information!

At Park Plastic Products our main focus is manufacturing custom fabricated tanks from polypropylene and co-polymer. Chemical rinse tanks, dip tanks, anodizing tanks, tank liners, air purification tanks, drip pans and custom rolled polypropylene tanks are available to be built to your size and specifications.

Experts in unique custom plastic extrusion products and complex secondary fabrications, Northland Plastics specializes in custom plastic profile extrusions such as extruded plastic tubing, rigid plastic profiles and flexible plastic profiles. Call Northland Plastics, Inc. for all your extrusion needs.

Thrust Industries is committed to quality in everything it does, from its technical knowledge to its customer service. As a leading plastic fabricator, the entire team at Thrust is devoted to developing high-quality solutions for your business and delivering them exactly when you need them. Thrust has served the needs of customers across the globe for over 3 decades— become one of them today.

Comco Plastics, Inc. offers precision machined plastic and custom fabrication including vacuum forming and plastic parts. We have highly skilled machinists and an array of CNC equipment available. Pellet to part manufacturing capabilities. From R&D to applications, we have the experience you need.

More Plastic Product Companies

Also, plastic substitutes for other materials like glass and metal can reproduce the qualities of those materials so accurately that they are sometimes confused for them. Acrylic plastic, for example, is characterized by its high optical clarity and is often used as a substitute for glass. Other plastic materials like PVC have also displaced traditional materials. Washers and plumbing pipes, which historically have been made of metal, are increasingly made of plastics like PVC. In addition to their capacity as alternatives to existing materials, the development of plastics has made possible the creation of products that never existed before. For example, plastic is almost universally the material of choice for the fabrication of non-conductive circuitry substrates.

There are many processes by which plastic products can be created. Extrusion is one of the most prominent plastic manufacturing processes. Extrusion involves heating and pressurizing a stock of raw plastic material and forcing it through a specially-shaped tool called a die. In the context of extrusion, a die is a hole cut out of a metal plate; when molten plastic is forced through the hole, it takes its shape. When the plastic emerges on the other side of the die, it is newly extruded plastic.

A plastic cutting process can then separate extruded plastic pieces from each other, and the pieces can then be shipped to customers or sent for additional processing. This process can be used only in the creation of plastic profiles. In order to create more complex shapes, a molding process must be used. Plastic molding processes also involve heating and pressurizing raw plastic, but they differ from extrusion in that they involve the injection of the plastic into a carefully shaped, hollow mold cavity.

In addition to these thermoforming processes, mechanical shaping processes like machining are also used to form plastic products. There is virtually no limit to the number of possible plastic products.

Die Cutting

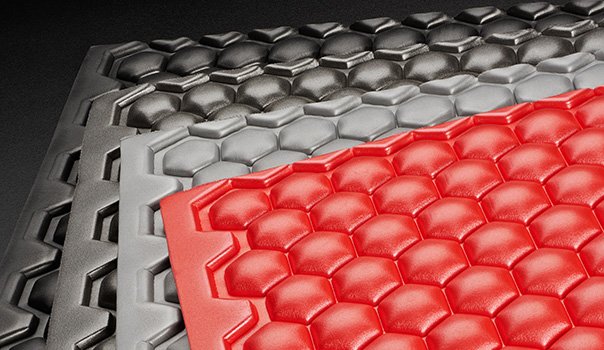

Die Cutting Foam Fab

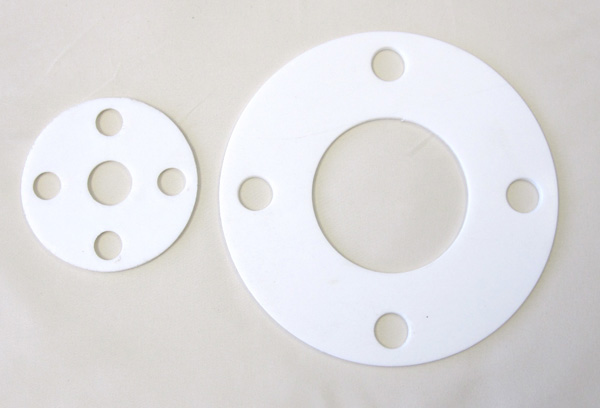

Foam Fab Gaskets

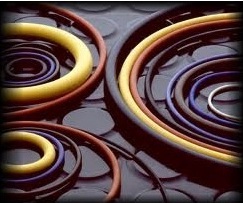

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services