Acrylic is a translucent thermoplastic with the molecular name Poly (methyl methacrylate). Acrylic is particularly used in retail for displays and signs. Acrylic is lighter and more durable than glass. Similar to metal fabrication, acrylic fabrication uses cutting-edge technology to shape and form acrylic plastic. To provide acrylic materials with the proper shape, size, and structure, the acrylic fabrication process includes mixing, extrusion, welding, laminating, acrylic foaming, vacuum foaming, and more. Read More…

We are accomplished plastic fabricators. The usability of our products is unmatched. We offer a plethora of secondary services for optional features. All of engineers are extremely thorough when creating these plastics. Your satisfaction is essential to us. You can count on us to give you exactly what you are looking for. Give us a call today to learn more information!

At Park Plastic Products our main focus is manufacturing custom fabricated tanks from polypropylene and co-polymer. Chemical rinse tanks, dip tanks, anodizing tanks, tank liners, air purification tanks, drip pans and custom rolled polypropylene tanks are available to be built to your size and specifications.

Experts in unique custom plastic extrusion products and complex secondary fabrications, Northland Plastics specializes in custom plastic profile extrusions such as extruded plastic tubing, rigid plastic profiles and flexible plastic profiles. Call Northland Plastics, Inc. for all your extrusion needs.

Thrust Industries is committed to quality in everything it does, from its technical knowledge to its customer service. As a leading plastic fabricator, the entire team at Thrust is devoted to developing high-quality solutions for your business and delivering them exactly when you need them. Thrust has served the needs of customers across the globe for over 3 decades— become one of them today.

Comco Plastics, Inc. offers precision machined plastic and custom fabrication including vacuum forming and plastic parts. We have highly skilled machinists and an array of CNC equipment available. Pellet to part manufacturing capabilities. From R&D to applications, we have the experience you need.

More Acrylic Fabrication Companies

Fabrication of Acrylic Plastics

Acrylic isn’t just transparent: it is available in many hues. Acrylic may also be fashioned to have opaque, mirror-like qualities. Two general categories of acrylic are extruded acrylic and its tougher counterpart, cast acrylic. Additionally, acrylic is available in various grades to accommodate different manufacturing techniques. These grades can determine thermal properties, light transmissions, fracture toughness, flow rates, and release capability.

Types of acrylic Plastic

Extruded Acrylic Plastic

Extruded acrylic is a sensible choice for basic fabrication and several applications because it is affordable. The translucent, moisture-resistant, extruded acrylic sheets are half the weight of glass. Extruded acrylic resists ultraviolet light degradation, making it clearer than glass and less likely to become yellow after prolonged sun exposure. In extrusion, acrylic monomers are heated, then delivered into barrels where a chemical reaction occurs. Depending on the direction of extrusion, the characteristics of extruded acrylic may differ. Extruded acrylic is more pliable, dimensionally stable, and cost-efficient than cast acrylic. The thickness is more uniform across extruded acrylic sheets. Extruded acrylic has a lower melting point than cast acrylic, making it more receptive to laser-cutting technology and easier to polish.

Cast Acrylic Plastic

Cast acrylic is created by mixing liquid materials in glass molds. Casting costs more because it’s labor-intensive. However, products made via casting are harder, more durable, and uniform. Casting is the recommended method for producing materials in applications containing perfumes, lotions, or other solvents. Cast acrylic will not bend, chip, or melt during machining. Cast acrylic is preferable for larger buildings or installations because extruded material has a thickness limit.

Uses of Acrylic Plastics

Protecting Furniture with Acrylic Plastics

Acrylic sheets are tougher and lighter than glass and are often used to protect furniture or surfaces.

Replacing Glass with Acrylic Plastics

Due to their durable construction, acrylic sheets are an acceptable substitute for glass on kitchen and bathroom cabinet doors. Acrylic sheets look strikingly similar to glass but reduce the risks of shattering.

Creative Sculptures made of

Spotted-glass windows and glass blowing are creative examples of sculpture. However, acrylic plastic can be used to exhibit the same artwork in place of glass. In natural settings, acrylic plastic is less prone to damage from accidents.

The Benefits of Acrylic Plastics

- Acrylic plastic is much stronger than plastic and is a useful alternative for outdoor uses of glass. Acrylic does not shatter dangerously like glass. Instead, acrylics break into dull, large pieces that are safer for cleanup.

- Acrylic plastics are lightweight and only half as heavy as glass.

- Acrylic plastics offer the highest levels of transparency and clarity for use in the optics industry.

Choosing the Right Acrylic Fabrication Company

To ensure you have the most positive outcome when selecting an acrylic fabrication company, it is important to compare several businesses using our directory of acrylic fabrication companies. Each acrylic fabrication company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or request a quote. Review each acrylic fabrication business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple acrylic fabrication companies with the same form.

Die Cutting

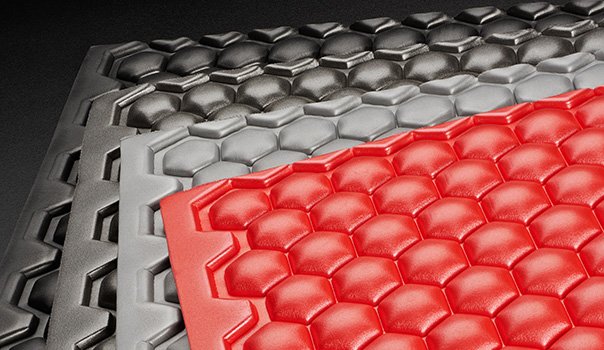

Die Cutting Foam Fab

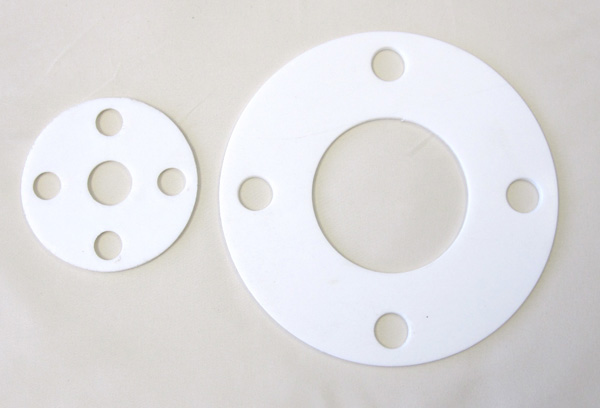

Foam Fab Gaskets

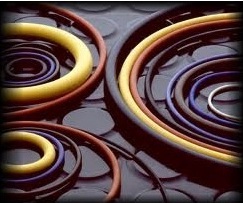

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services