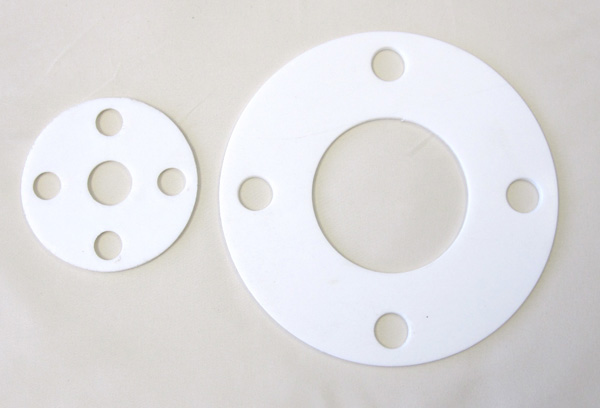

Plastic washers are discs with a center hole similar to metal washers and are used largely to spread the load of a fastener. Plastic washers prevent sparks due to their nonmetal nature, making the workplace safer and more dependable. In addition, plastic washers reduce maintenance downtime, which further streamlines manufacturing. Read More…

We are accomplished plastic fabricators. The usability of our products is unmatched. We offer a plethora of secondary services for optional features. All of engineers are extremely thorough when creating these plastics. Your satisfaction is essential to us. You can count on us to give you exactly what you are looking for. Give us a call today to learn more information!

Experts in unique custom plastic extrusion products and complex secondary fabrications, Northland Plastics specializes in custom plastic profile extrusions such as extruded plastic tubing, rigid plastic profiles and flexible plastic profiles. Call Northland Plastics, Inc. for all your extrusion needs.

Thrust Industries is committed to quality in everything it does, from its technical knowledge to its customer service. As a leading plastic fabricator, the entire team at Thrust is devoted to developing high-quality solutions for your business and delivering them exactly when you need them. Thrust has served the needs of customers across the globe for over 3 decades— become one of them today.

At Creative Design and Machining, we specialize in delivering high-quality plastic fabrication solutions that meet the unique needs of our customers across a wide range of industries. We take pride in combining innovative design capabilities with advanced machining techniques to produce components that are both functional and reliable.

More Plastic Washer Companies

Plastic Washer Material

Plastic washers are widely utilized in industries such as automotive, aerospace, electronics, construction, plumbing, and manufacturing, thanks to their versatile mechanical and chemical properties. Selecting the right plastic washer material is critical to ensuring optimal performance, durability, and cost-effectiveness for your specific use case. The ideal washer material depends on application requirements such as load-bearing capacity, resistance to chemicals and moisture, temperature range, and insulating needs. Below, we explore the most common types of plastic washers, their unique properties, and typical applications to help you make an informed purchasing decision.

Nylon Washers

Nylon washers are among the most popular choices for both industrial and commercial applications. Nylon is a highly elastic, synthetic polymer that provides outstanding flexibility, abrasion resistance, chemical inertness, and excellent machinability. Because of its superior absorption and insulating qualities, nylon washers are widely specified for electrical and chemical processing applications where exposure to solvents or corrosive agents is common. Nylon’s lightweight nature means these washers are also preferred in situations where reducing system weight is a priority, such as in automotive and aerospace assemblies. Furthermore, nylon washers are non-conductive, making them ideal for insulating fasteners in electrical enclosures and circuit boards.

Key benefits of nylon washers include:

- High strength-to-weight ratio for reliable load distribution

- Excellent resistance to abrasion, wear, and vibration

- Non-corrosive and impervious to most chemicals

- Superior electrical insulation properties

- Resilience in harsh environments, including outdoor and marine settings

Common Uses of Nylon Washers

Nylon washers are routinely used in electrical assemblies, plumbing fixtures, automotive dashboards, household appliances, and consumer electronics. They are also selected for noise-dampening, shock-absorbing, and vibration-resistant properties in power tools, HVAC systems, and sensitive instrumentation.

Teflon Washers

Teflon washers, also known as PTFE washers, are engineered from polytetrafluoroethylene—a fluoropolymer renowned for its extremely low coefficient of friction and remarkable resistance to water, oil, and most chemicals. Teflon exhibits superior thermal stability, allowing washers made from this material to function reliably in both high-temperature and cryogenic applications. These washers are also non-stick, making them an excellent option for food processing equipment and high-purity laboratory settings where contamination must be minimized.

Key advantages of Teflon (PTFE) washers include:

- Exceptional resistance to harsh chemicals and corrosive substances

- Low friction surface, reducing wear between moving parts

- Wide operating temperature range (from -328°F to 500°F)

- Non-reactive, making them suitable for pharmaceutical and food-grade applications

- Non-conductive and excellent dielectric properties

Where Are Teflon Washers Used?

Typical applications include plumbing and fluid handling systems, HVAC assemblies, automotive engines, precision instrumentation, semiconductor manufacturing, and chemical processing plants. Teflon washers are also preferred for sealing, insulation, and anti-stick requirements in food processing and pharmaceutical manufacturing environments.

Delrin Washers

Delrin washers are made from acetal homopolymer, a proprietary engineering thermoplastic that delivers exceptional dimensional stability, hardness, and mechanical endurance even under heavy-duty loads. Delrin’s robust crystalline structure makes these washers suitable for rigorous industrial, military, and high-performance commercial applications. They offer excellent resistance to impact, fatigue, and creep, as well as stable performance across a broad temperature range (from -58°F to 194°F / -50°C to 90°C).

Key features of Delrin washers include:

- Superior mechanical strength and stiffness

- High fatigue endurance and low moisture absorption

- Excellent dimensional accuracy for precision assemblies

- Resistant to solvents, fuels, and common industrial chemicals

- Low friction and wear-resistant, suitable for moving components

Delrin Washer Applications

Delrin washers are frequently utilized in gears, bearings, electrical insulators, automotive fuel systems, conveyor systems, and military-grade equipment. Their ability to retain mechanical properties under stress makes them a preferred choice for engineers seeking reliability and longevity in demanding settings.

Polyethylene Plastic Washers

Polyethylene washers, available in both high-density (HDPE) and low-density (LDPE) formulations, provide versatile solutions for a variety of sealing, spacing, and insulating needs. LDPE washers are favored for their flexibility, water resistance, and suitability in plumbing, irrigation, and water infrastructure projects. HDPE washers, on the other hand, offer enhanced toughness, rigidity, and resistance to crushing, making them ideal for heavy-duty industrial and mechanical applications.

Benefits of polyethylene washers include:

- Excellent resistance to moisture, acids, and alkalis

- Low cost and lightweight, facilitating economical large-scale usage

- Good electrical insulation and dielectric strength

- Flexibility (LDPE) or rigidity and crush resistance (HDPE)

- Non-toxic and safe for potable water and food contact applications

Polyethylene Washer Use Cases

Commonly found in plumbing fittings, valve assemblies, fluid delivery systems, and marine hardware, polyethylene washers are valued for their sealing capabilities and resistance to environmental stress cracking. Their non-corrosive nature also makes them suitable for outdoor and underground installations.

Other Specialty Plastic Washer Materials

Beyond the most common options above, several specialty plastics are used for washers in niche or advanced applications:

- Polycarbonate Washers: Known for high impact resistance and optical clarity, ideal for aerospace, automotive, and electronics industries where strength and transparency are required.

- Polypropylene Washers: Offering excellent chemical resistance and high fatigue life, these are used in laboratory equipment, chemical storage, and fluid systems.

- Polyvinyl Chloride (PVC) Washers: Resistant to weathering, chemicals, and UV light, PVC washers are suitable for outdoor fixtures, piping, and industrial machinery.

- Polyurethane Washers: Provide superior shock absorption, flexibility, and vibration damping, making them a choice for heavy machinery and high-impact environments.

- Phenolic Washers: Made from thermosetting resin, phenolic washers are valued for their high mechanical strength, electrical insulation, and heat resistance, commonly used in electrical panels and switchgear.

Manufacturing Plastic Washers

The process by which plastic washers are manufactured plays a significant role in determining their final characteristics and performance. Two primary methods are used: non-metallic stamping and injection molding. Each method offers unique benefits and is selected based on production volume, material type, and precision requirements.

Non-Metallic Stamping

Non-metallic stamping is an efficient, cost-effective method for producing high-quality plastic washers in large quantities. This process involves cutting washers from sheets or rolls of non-metallic materials—including nylon, PTFE, polyethylene, and more—using a punch press outfitted with steel dies. Non-metallic stamping is particularly advantageous for thin-gauge materials, rapid prototyping, and custom washer shapes that do not require complex geometry.

Advantages of non-metallic stamping include:

- Fast production rates for both standard and custom washer sizes

- Lower tooling and setup costs compared to molding techniques

- Ability to use a wide range of thermoplastics and thermosets

- Consistent thickness and dimensional accuracy

- Ideal for flat washer designs and high-volume orders

Stamping Process

The stamping procedure is highly valued in the plastic washer manufacturing industry for its scalability and efficiency. It utilizes a robust, high-production mechanical press to produce vast quantities of plastic washers, either in standard dimensions or tailored to customer specifications. Many plastic stamping facilities maintain an extensive library of dies, enabling quick turnaround for common washer types and sizes.

The core components of a stamping press include:

- Frame: Provides structural support and stability for the press

- Bolster Plate: Serves as the foundation for the die assembly

- Ram: Delivers the force necessary to punch washers from the plastic sheet

During operation, the frame is securely clamped to the bolster plate, while the steel die is attached to the ram. As the heavy ram descends, it exerts substantial pressure to punch out the washer shape with precision and speed. This streamlined process allows manufacturers to produce hundreds or even thousands of washers per hour, ensuring supply meets high-demand sectors such as automotive, construction, and electronics.

When Should You Use Stamping for Plastic Washer Production?

If you require large quantities of flat washers with consistent dimensions, or if you need quick prototyping for new designs, non-metallic stamping is often the preferred method. It is also ideal for projects where cost control and fast turnaround are essential factors.

Injection Molding

Plastic injection molding is the industry’s most widely used technique for producing complex, high-volume plastic washer components. This process is particularly advantageous for medium to large production runs of washers with intricate shapes, tight tolerances, or specific material blends that may be difficult to achieve with stamping alone.

Injection molding involves melting plastic resin pellets and injecting the molten material into a steel mold cavity under high pressure. Once cooled and solidified, the washer is ejected from the mold, resulting in parts that are highly uniform in size, shape, and physical properties. This technique is routinely used for engineering-grade plastics such as nylon, Delrin, PTFE, and high-performance blends.

Key advantages of injection molding include:

- Ability to produce washers with complex geometries, undercuts, and integrated features

- Consistent part quality and tight dimensional tolerances

- Efficient for medium to high production volumes

- Reduced material waste compared to machining processes

- Potential to use custom plastic formulations for enhanced performance

Is Injection Molding Right for Your Plastic Washer Needs?

If your application demands washers with intricate shapes, multiple material layers, or embedded components, injection molding offers the flexibility and scalability required. It is also the go-to method for manufacturing plastic washers for use in the electronics industry, medical devices, consumer appliances, and automotive assemblies where exacting standards must be met.

Advantages of Plastic Washers

Plastic washers deliver a unique combination of advantages over their metal counterparts, making them an increasingly popular choice for engineers, designers, and procurement professionals. Here are the main benefits that set plastic washers apart in a variety of industrial and commercial applications:

- Impact Resistance: Certain plastics like polycarbonate and polyurethane provide robust impact resistance, protecting sensitive components from shocks and mechanical stress. Nylon and polyurethane washers also help isolate stress points, minimizing the transmission of vibration and prolonging the life of assemblies.

- Fire Resistance: Many engineering plastics are available in flame-retardant grades, reducing the need for additional fire-suppression measures and often lowering insurance costs in high-liability environments. These washers comply with stringent fire safety standards and can withstand elevated temperatures without deforming or combusting.

- Vibration Resistance: Plastic washers are excellent for absorbing vibration and dampening noise, making them an ideal choice for rotating machinery, HVAC systems, and sensitive electronic equipment.

- Light Weight: The low density of plastics allows for significant weight reduction in vehicles, aircraft, and consumer products, improving fuel efficiency and ease of handling.

- Insulating Properties: Plastic washers are inherently non-conductive, offering outstanding electrical and thermal insulation for circuit boards, switchgear, and power distribution equipment.

- Food and Medical Usage: FDA-approved and medical-grade plastics ensure plastic washers are safe for use in food processing, medical devices, laboratory instruments, and pharmaceutical manufacturing, where sterility and non-reactivity are paramount.

- Low Cost: Plastic washers are generally more affordable than metal alternatives, both in terms of material cost and manufacturing expenses. They also require less maintenance over time due to superior corrosion and chemical resistance.

- Corrosion Resistance: Unlike metal washers, plastic variants do not rust or corrode, making them suitable for harsh environments and outdoor usage.

- Customization: Plastics are easy to mold, stamp, or machine into virtually any shape or size, allowing for custom washer solutions tailored to unique project requirements.

- Compatibility with Automation: Lightweight plastic washers can be easily integrated into automated assembly lines, enhancing manufacturing efficiency and throughput.

Buyer’s Guide: How to Choose the Right Plastic Washers

Choosing the ideal plastic washer for your application involves careful consideration of performance requirements, environmental conditions, compliance standards, and cost constraints. Here are key questions to ask and factors to evaluate when specifying plastic washers for your project:

- What mechanical stresses will the washer encounter? Consider load, vibration, impact, and fatigue to select a material with adequate strength and resilience.

- Does your application demand chemical or corrosion resistance? Choose PTFE, Delrin, or HDPE for exposure to acids, solvents, or corrosive agents.

- Is electrical or thermal insulation required? Nylon, PTFE, and phenolic washers are excellent for applications where non-conductivity is critical.

- What are the operational temperature extremes? Ensure the chosen plastic maintains its properties across the anticipated temperature range.

- Are regulatory or industry standards relevant? For food, medical, or aerospace use, ensure the washer material is FDA, NSF, or UL listed as needed.

- What is the required washer size, thickness, and tolerance? Review dimensional specifications and tolerances with your supplier to guarantee fit and function.

- What is your anticipated order volume? High-volume production may favor injection molding, while small runs or prototypes may be more cost-effective via stamping or machining.

- Are custom colors, shapes, or branding needed? Plastics can be easily customized for identification, aesthetics, or functional enhancements.

Engaging with an experienced plastic washer supplier early in your design or procurement process can help you assess all these variables and avoid costly rework or delays. Many suppliers offer engineering support, prototyping, and materials testing to assist in material selection and compliance verification.

Choosing the Correct Plastic Washer Supplier

To ensure you have the most beneficial outcome when purchasing plastic washers from a plastic washer supplier, it is important to compare several companies using our directory of plastic washer suppliers. Each plastic washer supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each plastic washer business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic washer suppliers with the same form.

What Should You Look for in a Plastic Washer Supplier?

When evaluating potential suppliers, consider factors such as:

- Quality certifications (ISO 9001, AS9100, FDA, NSF, UL, etc.)

- Material sourcing and traceability

- Custom design and prototyping capabilities

- Production capacity and lead times

- Technical support and engineering services

- Ability to provide documentation and compliance reports

- Reputation for on-time delivery and customer service

Partnering with a knowledgeable and reputable supplier ensures that you receive washers manufactured to your exact specifications, using certified materials and processes. This not only improves the reliability of your products but also safeguards against supply chain disruptions and compliance issues.

Frequently Asked Questions About Plastic Washers

What are the main advantages of plastic washers over metal washers?

Plastic washers offer lightweight construction, superior corrosion and chemical resistance, electrical and thermal insulation, cost savings, and easy customization. They are often chosen for environments where metal washers would corrode, conduct electricity, or add unnecessary weight.

Can plastic washers be used outdoors?

Yes, many plastic washers, including those made from nylon, HDPE, and PVC, are UV-resistant and weather-resistant, making them suitable for outdoor and marine applications.

Are plastic washers suitable for food and medical applications?

Absolutely. FDA and NSF-approved plastics such as PTFE, nylon, and certain grades of polyethylene are commonly used in food processing, beverage bottling, and medical device manufacturing.

How do I choose between injection molding and stamping for washer production?

Choose stamping for simple, flat washers and high-speed production of standard sizes in large volumes. Opt for injection molding when you need washers with complex shapes, integrated features, or tight tolerances, especially in medium to large quantities.

Can I order custom plastic washers?

Most plastic washer suppliers offer custom manufacturing to meet unique size, shape, color, and material requirements. Customization may involve specific formulations for increased UV resistance, antimicrobial properties, or compliance with regulatory standards.

Conclusion: Selecting the Best Plastic Washers for Your Application

Plastic washers are indispensable components across a broad spectrum of applications, from everyday consumer products to advanced industrial systems. Their unique blend of mechanical strength, chemical and electrical insulation, lightweight design, and cost-effectiveness makes them a smart alternative to traditional metal washers. By understanding the different types of plastic materials, manufacturing processes, and selection criteria, you can confidently source washers that enhance the reliability and longevity of your assemblies.

For optimal results, partner with a trusted plastic washer supplier who can provide guidance on material selection, compliance, and manufacturing options. Leverage supplier expertise and online resources to compare offerings, request quotes, and streamline your procurement process for any plastic washer need.

Die Cutting

Die Cutting Foam Fab

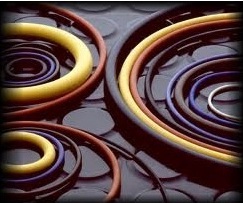

Foam Fab Gaskets

Gaskets O-rings

O-rings Plastic Fabricators

Plastic Fabricators Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services